Industrial vacuum cleaners for food industry

Food production must adhere to strict guidelines and certifications to ensure the safety and quality of food products. In addition, the food industry has its own inherent risks, including the spread of contaminants and the constant presence of combustible dust. To reduce these risks, food production facilities must implement appropriate controls and procedures, among which in several areas we find the use of industrial vacuum cleaners.

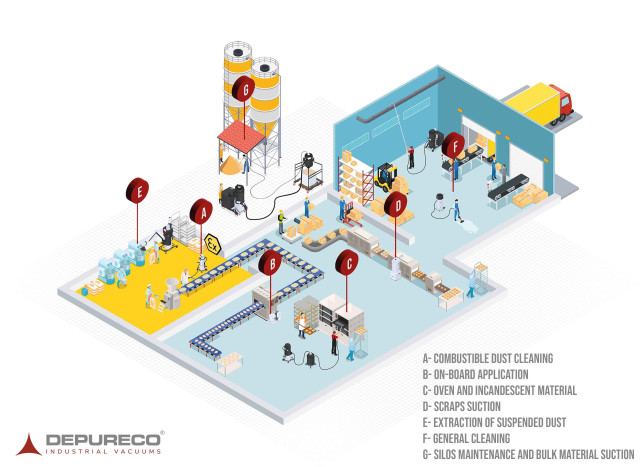

In this article we learn about the various applications industrial vacuum cleaners can have in the food industry and how they help ensure a safe and clean production environment.

Different processes, different suction solutions. Explore Depureco’s different suction solutions for your food production industry. Eliminate contamination and ensure the highest quality products!

Industrial vacuum cleaners for combustible dusts

Combustible dust is a serious hazard in the food industry, as it can cause serious explosions or fires. Industrial vacuum cleaners designed for combustible dust removal are usually Atex certified, equipped with explosion-proof, grounded motors and filters suitable for the type of dust to be vacuumed. These vacuum cleaners are essential to prevent dust accumulation and reduce the risk of explosions.

- Maximum safety through Atex certification for use in zones 2, 22 and 21

- Safe suction of combustible dust

- Antistatic filtration and accessories to prevent ignition

Suction of airborne dust

Airborne dust can be a safety hazard, as it can settle on surfaces posing a risk of product contamination. Industrial vacuum cleaners are equipped with powerful electric fans with large air flow and fitted with large filters and can effectively remove puffs of suspended dust, improving air quality and ensuring a safe and clean environment for food production.

- Suction of dust at the source

- Avoids cross-contamination

- Protects operators

Centralized vacuum systems for food industries

Centralized vacuum systems are an efficient solution for cleaning large production environments. These systems consist of a network of pipes and hoses connected to a central vacuum unit, which ensures a continuous cleaning process throughout the facility. These systems can be customized to meet the specific needs of each facility, providing a safe and efficient solution for industrial cleaning.

- Complete customization of the system

- Maximum efficiency of production facilities

- Cleaning even in multiple simultaneous locations

Industrial vacuum cleaners have become essential tools for the food industry, providing a safe and efficient solution for industrial cleaning. By choosing the right industrial vacuum cleaner for your facility, you can ensure a clean and safe environment for food production while improving the overall efficiency of the production process.