Sump vacuum cleaners for oil and swarf

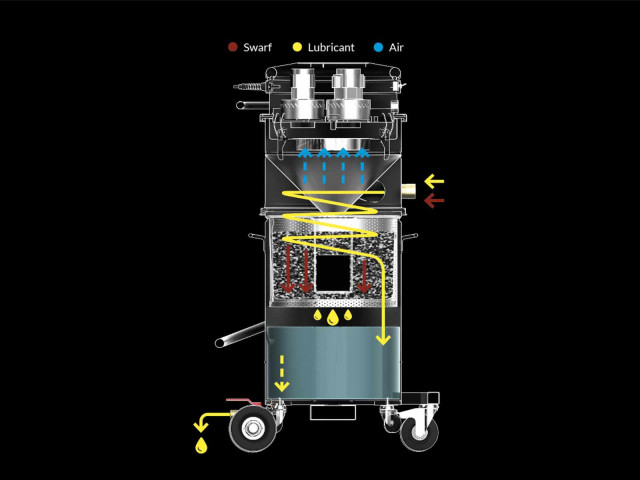

Industrial manufacturing processes involving metal cutting produce residual swarf mixed with cutting oil or lubricants that are commonly collected in tanks. The use of an industrial vacuum cleaner to separate cutting oil from metal shavings allows the filtered emulsions to be effectively recovered, disposing of excess shavings easily and safely. This helps maintain a clean working environment, improve machinery efficiency and reduce the overall environmental impact of industrial production processes.

- Recovery and reuse of filtered and cleaned cutting oils

- Savings on oil purchase and chip disposal costs

- Reduced maintenance time and downtime

Compact vacuum cleaners with liquid capacity up to 100 liters

Compact and powerful industrial vacuum cleaners designed to suck up oils and chips with an integrated liquid discharge system. They are equipped with a level control, a float switch and a grating basket for easy separation and disposal of sucked metal chips.

Industrial vacuum cleaners with liquid capacity up to 300 liters

Powerful vacuum cleaners designed to suck up medium amounts of oil and chips with a reverse flow liquid discharge system or submersible discharge pump. They are equipped with a level control, a float switch and a separable basket for easy separation of chips and sucked liquid. By using different levels of filtration, these vacuum cleaners ensure safety and durability even when sucking muddy sludge.

Vacuum cleaners with liquid capacity up to 1000 liters

Industrial vacuum cleaners designed to handle large quantities of oil and metal swarf, thanks to the integrated fast liquid discharge system that also allows simultaneous suction and discharge of sucked and filtered oils. They are ideal for cleaning and maintaining tanks of large CNC machine tools, even in the presence of dense sludge.

INDUSTRIAL VACUUM RAM OIL 500

4,3 kW

500 Lt

INDUSTRIAL VACUUM RAM OIL T500

4,3 kW

500 Lt

INDUSTRIAL VACUUM RAM OIL T555

5,5 kW

500 Lt

INDUSTRIAL VACUUM RAM OIL 1000

5,5 kW

1,000 Lt

INDUSTRIAL VACUUM RAM OIL 1000 AV

5,5 kW

1,000 Lt

Oil mist vacuum cleaners

Vacuum cleaners used to remove oil mists or oily emulsions from the air in an industrial work environment. Using a filtration system, they capture oil or emulsion particles in the air and prevent their dispersion into the surrounding environment. They are important devices for maintaining a safe and healthy working environment.