Dust extractors for construction dust

Construction jobs are known to be among the dustiest and also among the most dangerous for workers. Each phase of work has its own hazards, but mitigation of the dust generated is practically a constant.

Floor preparation machines such as scarifiers, grinders, shot blasters and core drills are used in various industries for surface preparation and treatment. However, during their operations, these machines generate a large amount of dust, which can be a safety hazard for workers as well as a source of environmental pollution. Dust extractors are essential tools for maintaining a safe and clean environment for workers and the surrounding area. For example, floor preparation machines such as scarifiers, grinders, gritters and core drills are used in various industries for surface preparation and treatment. However, during their operations, these machines generate a large amount of dust, which can be a safety hazard for workers as well as a source of environmental pollution. Industrial vacuum cleaners are essential tools for maintaining a safe and clean environment for workers and the surrounding area.

Dust extractors for floor scarifiers

Floor scarifying machines are used to remove coatings, such as paint or adhesives, from surfaces. This process generates a large amount of dust that can be a safety hazard and a source of environmental pollution. Vacuum cleaners designed for use with floor scarifying machines have powerful suction and specialized filtration capabilities to capture and contain dust, ensuring a safe and clean environment for workers and the surrounding area.

Dust extractors for shot blasters

Shot blasters are used to clean and prepare surfaces for coatings or surface finishes.

Floor shot blasters are used to level and polish surfaces. Vacuum cleaners designed for grinders are equipped with powerful suction capacities, specialized filters, and automatic filter cleaning systems to improve the efficiency and durability of the machines.

How to choose the right dust extractor

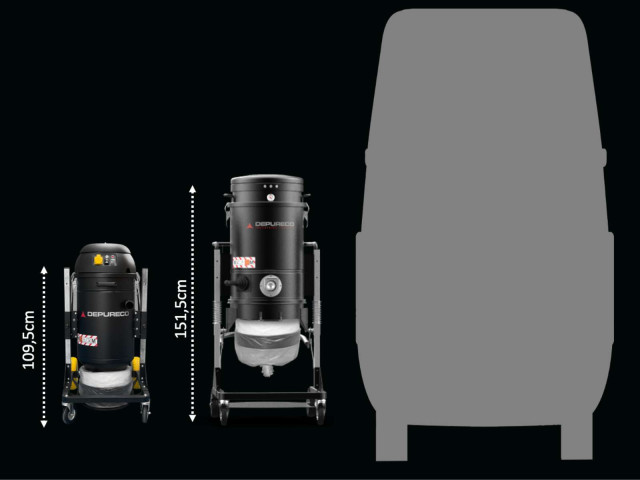

The right model of dust extractor is the one that has the features best suited to the type of application to be performed or the type of machinery it will have to work with.

The most important characteristics are:

Absolute filtration

One of the main features of dust extractors is their ability to filter and retain all dust sucked in during work. Industrial vacuum cleaners with absolute HEPA filtration are able to effectively remove even the smallest particles with particle sizes down to 0.18 microns, thus ensuring higher air quality within the working environment.

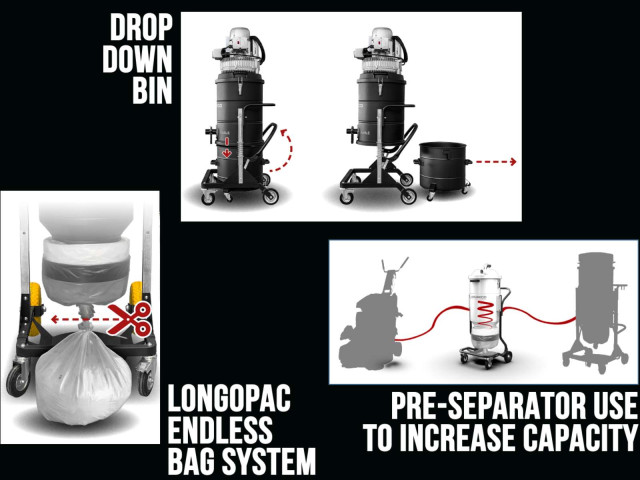

Management and disposal of vacuumed dust

Another important feature of industrial vacuum cleaners is the ability to properly handle and dispose of sucked dust. Some dust collection systems, such as the Longopac continuous roll, enable operator-safe handling and disposal of vacuumed dust.

Why choose a dust extractor for floor, surface and construction dust preparation machines

Dust extractors are essential tools for maintaining a safe and clean environment when using floor and surface preparation equipment. By choosing the right vacuum cleaner for your equipment, you can ensure a safe and healthy workplace for workers and minimize the risk of environmental pollution. Whether you use hand tools, scarifiers, sanders, shot peening machines or core drills, dust extractors are a necessary investment to protect the safety and health of workers and the environment.