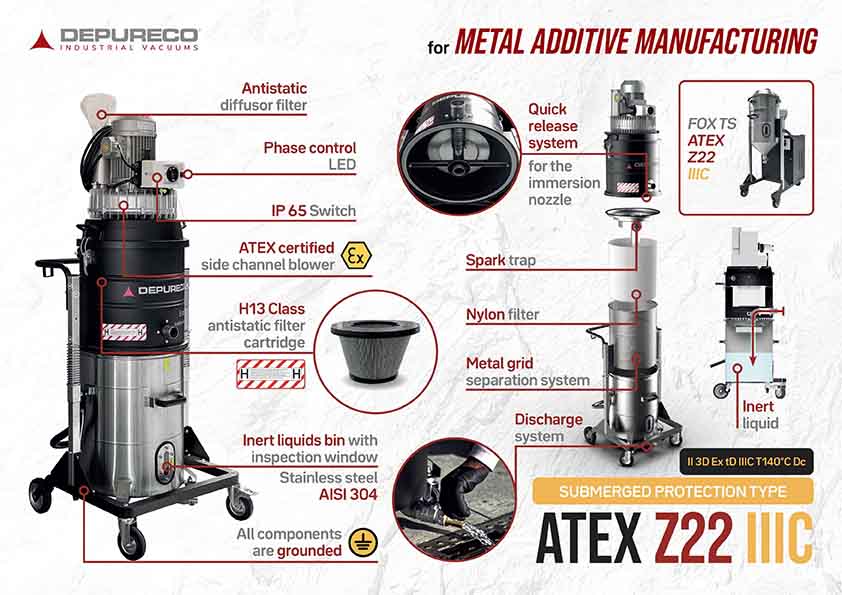

The ECOBULL Additive Manufacturing is an industrial vacuum cleaner, ATEX Z22 and IIIC certified, designed for the suction of conductive metal powders in the additive 3D printing sector. A powerful ATEX-certified side channel turbine powers the ECOBULL AM. The unit is equipped with a sophisticated explosion-proof system for the aspiration of conductive metal powders, which is obtained by immersing the collected material directly in an inert liquid bath. The motor is protected by a large surface (35,000 cm2) class H13 antistatic conical filter. Filtration also takes place through a metal grid filter and a nylon filter, capable of separating the metal particles from the inert liquid, to be recovered and reused. The liquid is discharged by gravity through a practical tap placed on the bottom of the container. The 100 Lt container is made of AISI 304 stainless steel and is equipped with a convenient inspection window on the front to check the level of the liquid inside.

Other articles

CASE STUDY: centralized vacuum system for welding fumes

16/01/2024

Read

Additive Manufacturing: download our new catalog

10/11/2023

Read

New Extraction Arm: revamp your vacuum into an unbeatable dust extractor

02/11/2023

Read

M70 OIL: discover the new compact and easy-to-handle industrial vacuum for oil and swarf

04/10/2023

Read

New Cyclone Pre-separator: designed to handle fine dust efficiently

12/06/2023

Read

Vacuum solutions for briquetting presses: Case Study

01/06/2023

Read

New Depureco Company Profile

01/02/2023

Read

THE NEW CENTRALIZED VACUUM SYSTEMS CATALOG IS HERE!

12/10/2022

Read

Avoid Silica Dust Exposure with an Industrial Vacuum from Depureco.

03/08/2022

Read

Depureco Forest is now at +7500 trees! 🌳

27/07/2022

Read