INDUSTRIAL VACUUM

TX 400 P

Heavy duty Three-Phase Industrial Vacuum Cleaners

The TX 400 P industrial vacuum stands out for its power, maneuverability, and compactness. Fitted with a 4 kW side channel turbine, ideal for working continuously without the need for maintenance. The filter chamber contains a large surface (24,000 cm2) polyester filter, certified as M Class (1-micron filtration efficiency), ideal for working with even the finest dust. In this industrial vacuum of the Depureco three-phase range, a different filter can be installed depending on the professional application. Teflon water-repellent filters, Nomex 250°C resistant filters, and filters with PTFE treatment for more binding and difficult dust are also available. The unit can be fitted with an H14 absolute filter on demand. The TX industrial vacuum is equipped with a large 65Lt or 100 Lt detachable container on wheels allowing the operator to empty the vacuumed material easily. Disposable collection bags can also be used. A floating system can be provided in the container to vacuum liquids in complete safety.

INDUSTRIAL VACUUM

TX 400 P |

Highlights

SUCTION UNIT

The suction unit is a side channel blower with direct coupling between motor and impeller. The side channel blower is equipped with a safety valve to guarantee continued work in complete safety, without any maintenance. The blower is also equipped with a metal silencer to maintain a low noise level.

FILTERING UNIT

The filtration is guaranteed by an M class polyester filter. The star shape enables air to flow through the filter even when it is dirty. The fabric of the filter is classified as M Class (BIA | EN 60335-2-69). This means that all particles till 1 micron are stopped by the filter so as to protect the blower and the operator around the vacuum cleaner.

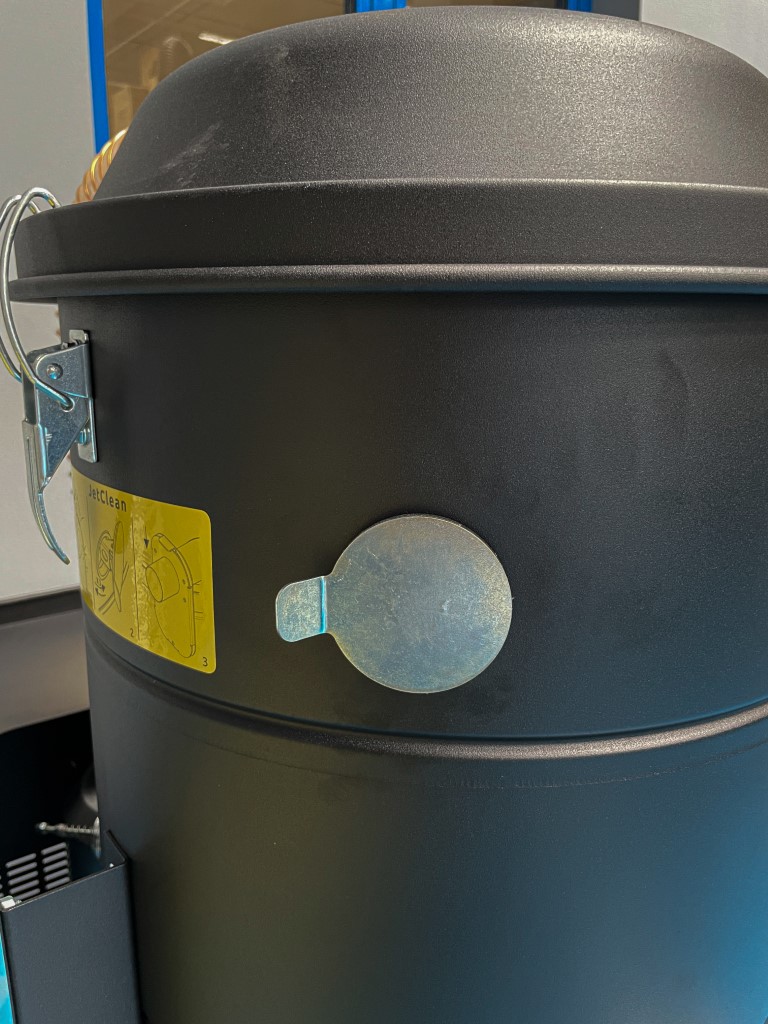

FILTER SHAKER

On one side of the filter chamber there is an ergonomic manual shaker through which the operator can easily and quickly clean the filter, removing any dust and debris from its surface. Thanks to this smart cleaning system the operator can carry on working without needing to change or wash the filter.

COLLECTION BIN

The material is collected inside a painted container equipped with a metal handle which enables the bin to be detached from the machine. Thanks to its 4 swiveling wheels, the bin can be easily moved and emptied. Each wheel is reinforced to guarantee maximum stability during handling.

INDUSTRIAL VACUUM

TX 400 P |

Technical data

Motor

| Type | side channel blower |

| Voltage | 400 V |

| IP | 55 |

| Continuous vacuum | 160 mBar |

| Maximum air flow | 530 m3/h |

| Safety valve | opzionale |

| Noise level | 76 dB(A) |

| Frequency | 50/60 Hz |

| Power | 5,5 HP |

| Insulation class | F |

Primary Filter

| Type | star filter |

| Class EN 60335-2-69 | M Class |

| Media | polyester |

| Filter cleaning | manual shaker |

Machine

| Suction inlet | 70 Ø mm |

| Dimensions | 650 x 1100 mm |

| Height | 1400 mm |

| Weight | 140 Kg |

INDUSTRIAL VACUUM

TX 400 P |

Options

AVAILABLE FILTER MEDIA

ANT M

Antistatic filter (M class EN 60335-2-69)

MTF

Teflon filter (M class EN 60335-2-69)

NOMEX

250° Celsius resistant filter

PTFE

PTFE Filter (M class EN 60335-2-69)

PTFE ANT

AntistatIc PTFE filter (M class EN 60335-2-69)

HEPA 14

Absolute filter (EN 1822)

28.000 cm² filter surface

H14 Class Filter (EN 1822)

Glass fiber

28.000 cm² filter surface

H14 Class Filter (EN 1822)

Glass fiber

AVAILABLE FILTER CLEANING SYSTEMS

COM

Compressor on board

Compressor fitted on the back cover

Compressor fitted on the back cover

JC

Jet Clean

PSC

Semiautomatic pneumatic filter shaker

SP

Automatic reverse jet cleaning system

Antistatic M class filter (EN 60335-2-69), 3 Polyester filter cartridges, 9 m² filter surface

Antistatic M class filter (EN 60335-2-69), 3 Polyester filter cartridges, 9 m² filter surface

STRUCTURE AND OPTIONS

BX

Stainless steel bin AISI 304

GX

Stainless steel bin and chamber AISI 304

TX

Stainless steel bin, chamber and frame AISI 304

FKL

Forklift bracket

FLT

Floater device

GFR

Lifting eyebolts

GRD

Grounding

KDP

Differential pressure KIT for bag

LP

Longopac bagging system

PRV

Pressure relief valve installed

SD

Sliding damper

TAN

Tangential inlet + cyclone

INDUSTRIAL VACUUM

TX 400 P |

Accessories

P10866

Iron reducer ø 70/50mm

Reducer for vacuum quick fitting in galvanised steel 70/50 mm diameter

P11887

Wet & Dry Kit Ø 50mm

Kit containing specific accessories for 50 mm diameter solids and liquids vacuuming

P12350

Starter kit Ø 50mm

Basic kit containing specific accessories for 50 mm diameter solids and liquids vacuuming

INDUSTRIAL VACUUM

TX 400 P |

Gallery